Case study: Environmentally friendly and efficient water treatment for ultrapure water

Our customer needs approx. 300 litres of perfectly treated ultra-pure water with low conductivity per hour at a pressure of 4 bar for its mirror production. Additionally, approx. 2000 l immediately available ultrapure water is required for each production start, and the customer wanted to find a long-term and efficient solution, apart from the usual ion exchangers. Resin required for ion exchangers is becoming increasingly difficult to obtain and prices are currently rising steadily.

Thus, the task of IMEX Filtertechnika was clearly defined: supply of a high amount of pure water for discontinuous demand, long-term calculable costs and operational reliability.

In its analysis, the customer assumed that the new plant should have a minimum capacity of 500 l per hour. IMEX's team of experts was able to draw on the experience gained from a smaller pilot project already installed in 2019 and devise a customised solution. The smaller project with a capacity of 80 l per hour has been running absolutely bacteria-free since it was commissioned more than a year ago.

Based on this, three systems were successfully combined in a complete unit in order to bring the Sopron city water to the desired degree of purity on the one hand, and to provide for the initial capacity of 2000 l on the other.

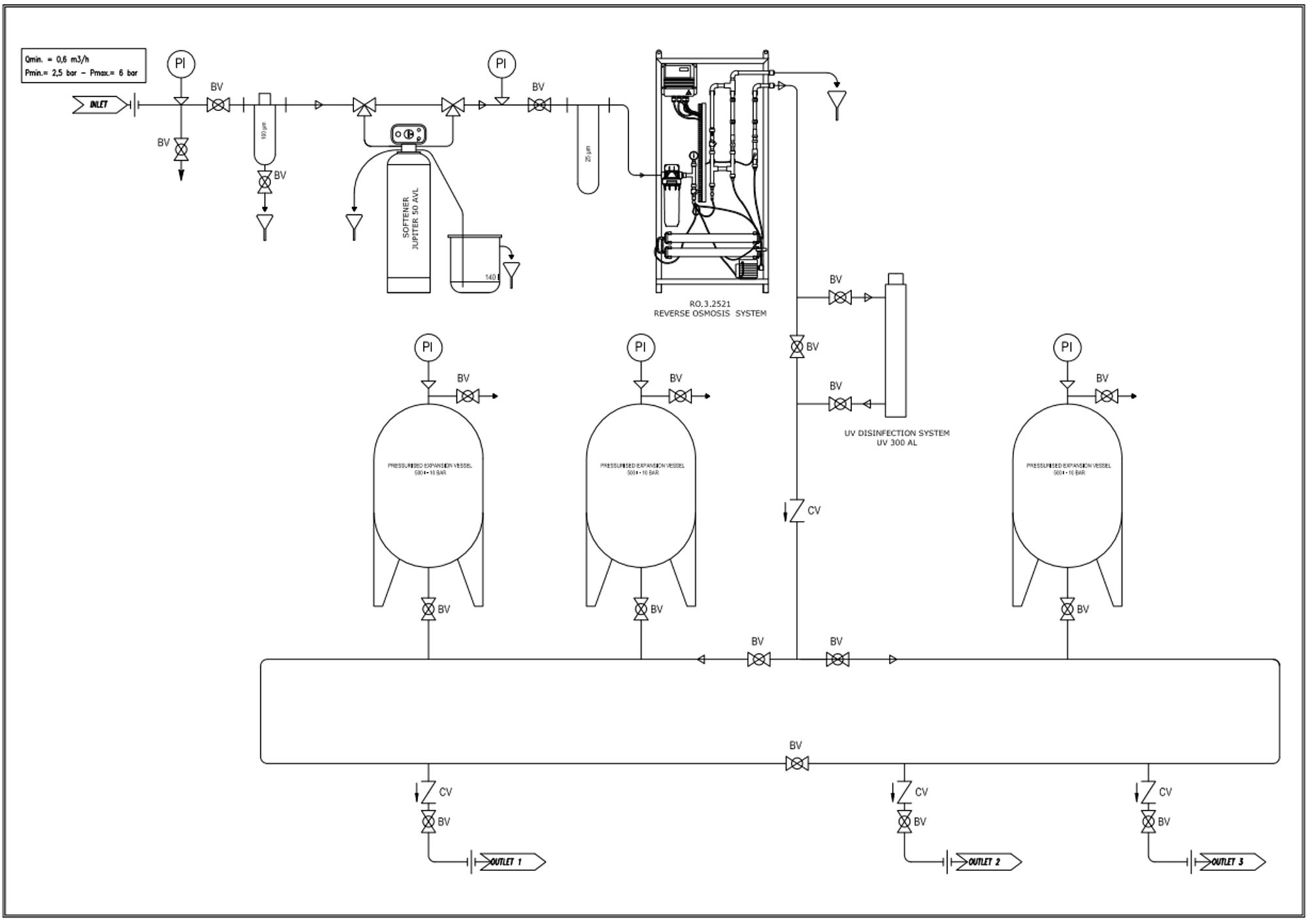

The first element of the system is a softener unit. This is followed by a reverse osmosis unit with an output of 300 l of ultrapure water per hour, equipped with a UV disinfection system and 4 buffer tanks for a total capacity of 2000 litres.

Reverse osmosis: Environmentally friendly, reliable and calculable

Reverse osmosis technology is comparable to extremely fine filtration and is therefore also called hyperfiltration. This method uses the reversal of a process that has elementary significance in nature: osmosis. The name refers to the process of equalising the concentration of two liquids through a semi-permeable membrane.

In reverse osmosis, water is pressed against a synthetic semi-permeable membrane that is permeable to water molecules but impermeable to impurities in the raw water e.g. hardness components, salts, lime, nitrate, residues of pesticides, hormones and medicines, microorganisms, to name but a few. The pressure on the side with high ion concentration (tap water, raw water) pure water molecules are forced to move to the pure water side with lower concentration. On the raw water side, a high concentration of retained substances is produced during operation, which must continuously be flushed and discharged as waste water.

Besides being environmentally friendly, this water treatment technology also has the advantage of cost clarity. The purchase and maintenance costs of the system can be calculated in the long term. Maintenance costs of ion exchangers however, have become increasingly difficult to calculate in recent years, as on the one hand the price of resin has already risen to € 4 per litre, and, on the other hand, a shortage of raw materials may lead to uncertainties in availability and further price increases.

Amortisation under one year

Our customer has confirmed to IMEX Filtertechnika that after 6 weeks of successful operation, monthly savings in resin costs of around € 1,600 can already be observed. Meaning the purchase costs of the system have already been amortised within the first year. ROI < 1 year

Facts and figures on the water treatment unit

IMEX Filtertechnika compiled all relevant data and investigation results into a proposed solution that includes the comprehensive treatment of Sopron's municipal water and all customer requirements.

As a solution, a fully automatic water treatment unit was designed, consisting of the following components:

- 90 µm filtration: backflush filter

- Softening: 50 AVL

- 25 µm filtration: candle filter

- 10 µm filtration: activated carbon filter (built in the RO unit)

- 1 µm filtration: candle filter (built in the RO unit)

- Osmosis unit

- UV fertilization

- 4 storage tanks

Scheme of the system conception