Integrity test

Regular validation of ventilation systems ensures product quality and protects against extreme costs in the event of a product recall.

Production facilities in which pharmaceuticals, medicines, cosmetics, microelectronics and also foodstuffs are produced, must conform to the highest hygienic standards of a clean environment. In order to reliably avoid even the smallest contamination in such production areas, cleanrooms or even sterile cleanrooms are mandatory. Air quality and purity are then ensured by complex ventilation systems. The HEPA filters used in this process must be subjected to regular integrity tests in accordance with ISO 14644 and GMP before and also during operation. During tests filters are checked for their tightness and reliability in retaining particles and germs.

If something happens, the date of the last check counts

In the pharmaceutical sector in particular, regular integrity checks also protect against high costs in the event of a product recall. Because in the event of product contamination, all products that have been put into circulation with a positive result since the last verifiable integrity test are affected by the recall.

Get the assurance that your cleanrooms meet all GMP requirements with the filter integrity test of IMEX Filtertechnika. We test reliably, qualified and optimally adapted to your needs.

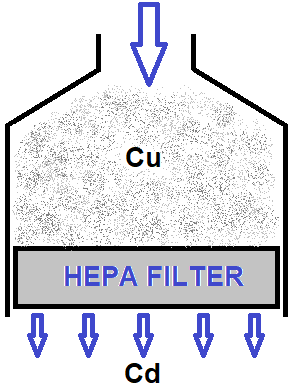

IMEX Filtertechnika Kft. has one of the most modern, newest test equipment sets, as well as a team of experts with many years of experience. Because the integrity test of HEPA filters requires sensitive, highly specialized test equipment on the one hand, and special expertise on the other. A finely atomized mist is fed over the filter medium by means of an aerosol generator. The associated photometer measures and compares the concentration measured under the filter with the concentration measured above the filter. This test reliably determines whether the filter has a leak or whether it is not properly sealing somewhere.

Example of a H14 Test:

H14 integral efficiency criteria:

- MPPS integral efficiency: ≥99,995%,

- MPPS local efficiency: ≥99,975%

- DOP local efficiency ≥99,99%

In case of integrity checks of H14 HEPA filters 0.010% feed-through is set as alarm value. That means, 10000 particles (Cu) before the filter, 1 particle (Cd) after the filter => efficiency 99.990% (local).

Reliable air hygiene in operating theatres, cleanrooms and sterile rooms

As a certified and experienced service provider, IMEX Filtertechnika offers you numerous tests relating to technical air hygiene and ventilation certification. Our experienced team supports you with a range of services that are required and prescribed for the standard, safe and clean operation of ventilation systems.