Our contribution to Industry 4.0 – The FMS Remote Filter Monitoring System from IMEX Filtertechnika

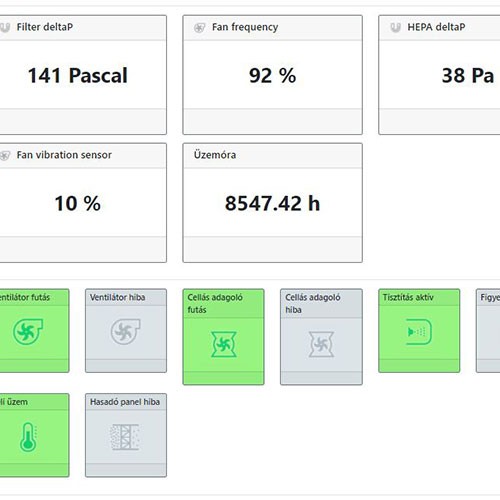

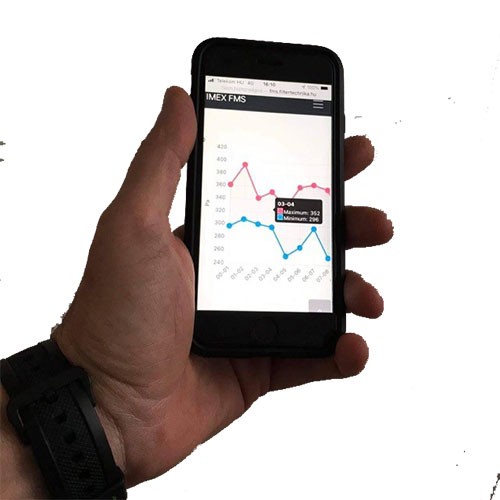

Imagine you were able to view inside of a dust collector system while in operation. You could simply have an overview of all functions in real time: the operation status and working hours of the fan unit, the suction capacity of the equipment, the contamination level of the filters, the pressure, with which the filter is cleaned, and also its intervals or even the number of impulses. You could get instant alerts to your E-mail if any value is out of the normal range. You could review the logged data from anywhere, even if the unit is switched off. IMEX Remote FMS monitoring takes care of all these defined measurements and logging, and gives the user the chance to make immediate adjustments in order to optimize performance and avoid severe malfunctions.

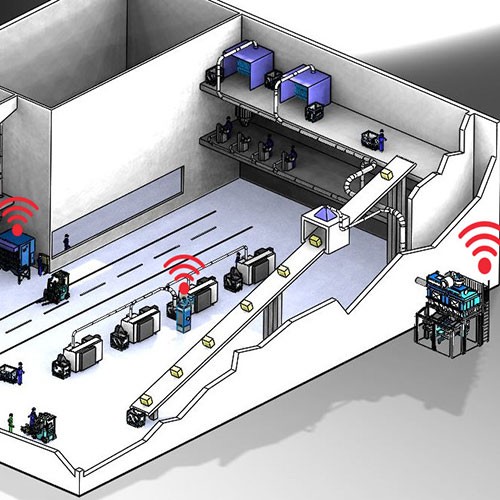

Businesses have plenty of possibilities to use intelligent networking. By developing FMS, IMEX Filtertechnika have mainly focused on the dust collection equipments delivered installed and serviced by us, however, the system may be, of course, easily adapted flexibly to any other duxt collector system, and other applications e.g. ventilation and air-conditioning systems or compressors.

Industry dust collectors are widely used everywhere: from metal- and woodworking plants to industrial food and fodder production. Our Remote FMS field units are communicating on secure channels and only with our own server, so data can be safely accessed from anywhere via Internet, and in case of system parameters out of normal range, you can be instantly alerted to act fast, and avoid possibly costly maintenance issues interfering with the operation of the equipment. Reviewing logs and trends also can help you to plan maintenance in advance accordingly.

Availability: prompt query of the actual operating status

The most important data of the monitored systems (e.g. information on operating status, error messages, information on pressure and temperature levels, etc.) are available from anywhere. Data is are accessible in real time, also a system check is available anytime via a PC, tablet or mobile device with internet connection. This ensures maximum availability, from anywhere, anytime.

Data security: diagnostic and Optimization Analysis

Logged data are saved to our own hosted server. Therefore data (the most recently saved data) are also available in case the investigated system is shut off or detached from the electric mains. In case of an outage important data are subsequently available. Thus the FMS provides a valuable source of analysis for a quick diagnosis and troubleshooting, as well as to compare selected intervals, to analyse operating status trends and enable in depth optimization.

System security: detect malfunctions before they become an issue

Even a small deviation in a sophisticated technology system can trigger a sequence of events, which can lead to serious issues as time passes. FMS can automatically send an e-mail to the service and maintenance team and inform them about such deviations immediately in order to shorten response times and evade bigger issues.

Cutting costs: no unexpected downtime

Unexpected downtimes and production outages become avoidable if smaller errors are detected and remedied early enough. An ideal maintenance date, based on the actual operating status of the equipment, may reduce the number of unexpected maintenance work, consequently, operation costs can be optimised.

Industry 4.0: interconnected filtration services for a boost of efficiency

IMEX Filtertechnika provides an innovative contribution to Industry 4.0 and the Internet of Things with its Remote Filter Monitoring System, by enabling a smart network of machines and processes by using information and communication technology. The innovative power of this technology stems from the provision and procession of measurement data as well as real time conditions (e.g. cold, dry, full, empty) for a network that computes an impact to the technological system.

The benefits of IMEX Remote FMS:

- Manufacturer independent

- Flexibly adaptable to extraction equipment, ventilation systems or oil filtration units

- Industry 4.0 capable

- Available from anywhere via the Internet

- External data security in case of a system outage

- Cost reduction

We are happy to offer you our FMS as part of a service contract in order to regularly check and maintain your systems.