The advantages of 3D planning based on 3D scans

The plant in Nagyigmánd has existed for many years and the production plant in the factory hall was a fixed, unchangeable component with which it had to be planned. This resulted in some special challenges in the planning and subsequent installation of a modern, high-performance dust removal system.

The biggest challenges in planning were:

- An existing multi-storey factory building whose structure and arrangement of equipment inside could not be changed

- The planning of the ideal pipeline routing and its anchoring

- Consideration of the properties of the separated dust in the dimensioning of the pipelines, especially with regard to the risk of explosion.

- Planning and scheduling of the installation without disrupting operations and production

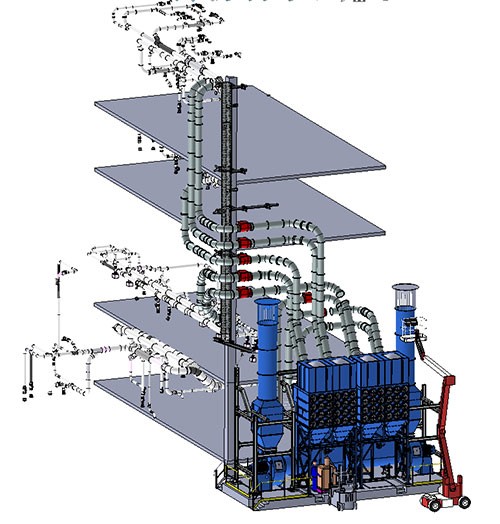

Our planning experts in IMEX’s Industrial dust and oil mist filtration department were able to develop an accurate 3D plan using extensive scans of the factory hall. This involves using a 3D laser scanner to create a detailed digital spatial plan of the factory hall. With the help of special software, the entire space is mapped and every last detail is made visible and measurable. All existing elements are taken into account: The fixed components of the architecture from columns to hall ceilings to electrical outlets just as well as the existing equipment from pipelines and machines. Even places that are difficult to access can be measured with millimeter precision and visualized on the computer.

This made it possible to coordinate everything precisely with the customer long before the first screw was installed. The IMEX experts are used to finding real "crawl spaces" for pipelines. This involves not only the most efficient pipeline routes, but also checking for overlaps (collision detection) in order to eliminate potential sources of danger.

IMEX Filtertechnika has more than 20 years of experience in 3D scanning technology and planning. This detailed and accurate planning naturally has a direct positive effect on the safe and efficient implementation of a project, which has been confirmed by the international engineering team of Bayer to IMEX Filtertechnika Kft.:

May 2022:

"Miklós, Construction team,

In general I have to confirm my cooperation in this project with IMEX as a professional experience with positive reactivity and very good sense of our specific requirements on quality and safety. With the final stretch in sight I don't want to jinx it, but we are completing this project with zero incidents in a very short and intense period, thank you and the complete team for this.

Many thanks for making this project happen. We are at the final stage and we can say that we did it on the most possible safe way in the fastest possible way.

Please follow the remaining items to conclusion and we can all be proud of ourself that we created this wonderful solution to a long lasting problem."

Best regards,

Gino Jacobs

EMEA Engineering / Project Manager

"Hello!

It was a pleasure working with you.

It would be nice if other contractors would approach your safety standards.

Thank you."

Best regards,

Zsolt Horvath

HSE Coordinator