Compressed air preparation

Compressed air filters, water separators and compressed air dryers - the full range for individual solutions.

Many users are not aware of the amount of water and the amount of contaminants that can be generated by the use of a compressed air system. In addition to water vapor, compressed air can contain various contaminants such as dirt particles (dust, soot, etc.), oil vapors, solvent vapors, and many other substances. In short, solid particles, water and oil are named as the three primary contaminants.

In compressed air treatment, these impurities are specifically removed from the compressed air according to the requirements of the application. The aim is to provide exactly the quality required for trouble-free application. The corresponding quality class is expressed and described in the ISO 8573-1 standard.

Due to the various possible contaminants, different processes also intertwine during compressed air preparation. A particular additional challenge is the exposure to germs and bacteria - but these are regulated in their own standards.

Methods of compressed air preparation for ISO 8573-1 are

- A) Drying

- B) Filtration

Compressed air drying

Residual moisture or water is the most problematic of all contaminants in compressed air. On the one hand, it causes damage due to corrosion, and on the other hand, it also promotes the growth of microorganisms that can contaminate products and thus harm people and other living creatures.

With the help of suitable dryers, the required degree of residual moisture can be produced. Two processes are used particularly often:

- Refrigeration dryer

- Adsorption dryer

The selection criteria for the application include pressure dew point, volume flow and, of course, compressed air quality requirements. Our experts will be happy to advise you on the best solution in terms of system quality and economy.

Refrigeration dryer

These are usually used at the beginning of the compressed air system, often after suitable water separation and condensate removal.

Refrigeration dryers are the most economical method of drying compressed air. By cooling the compressed air temperature, the entrained water vapor condenses to water, which is then discharged.

High-quality refrigeration dryers are equipped with a condensate drain as standard and thus avoid costly compressed air losses. Today, compressed air refrigeration dryers are common state of the art and usually the preferred choice. They are suitable for use in industry, trade and workshops.

Adsorption dryer

If extra-dry compressed air is your requirement, or very large volume flows are needed, then adsorption dryers are the suitable devices for treatment.

Depending on the type of application, cold or hot regenerating adsorption dryers or even oil-free adsorption systems are used.

High-performance adsorption dryers from Donaldson, for example, allow a pressure dew point down to -70 °C and, combined with prefilters and afterfilters, guarantee dry, oil-free compressed air.

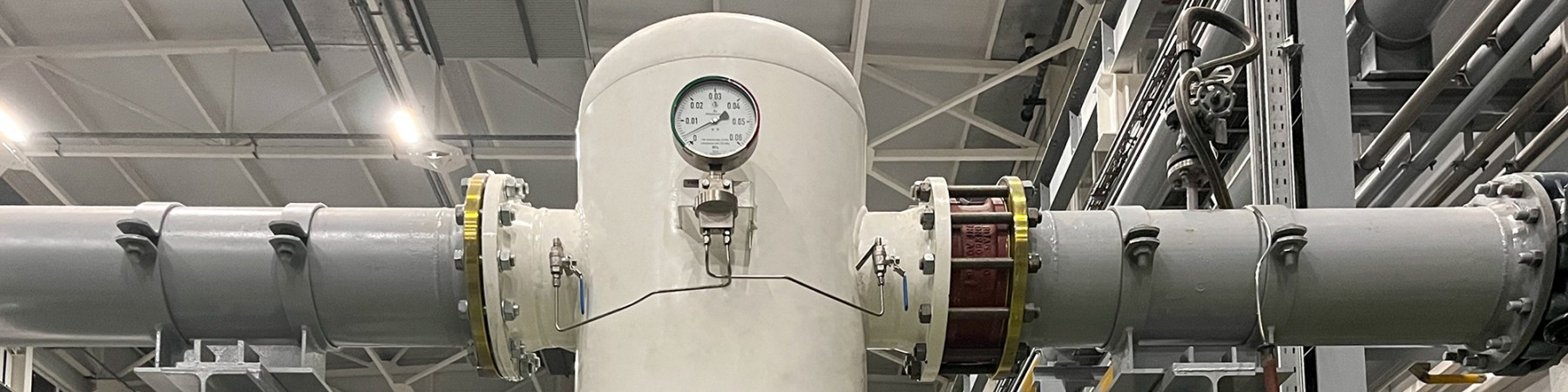

Filters for compressed air treatment

Depending on the required cleanliness class, several compressed air filters are often connected in series for improved compressed air treatment: Water separator, coarse filter or dust filter, fine filter, ultra-fine filter and activated carbon filter. We offer a wide range of housings and filter elements matched in terms of size and volume, which are designed precisely for the respective filtration tasks. Our portfolio includes all types of housings with threaded and flanged connections:

- Aluminum housing

- Steel housing

- Stainless steel case

A large selection in the field of filter elements and accessories is of course also part of our offer.

Performance data validated according to ISO 12500-1 (oil aerosols), 12500-2 (oil vapors) and 12500-3 (particulates) - Reliable compressed air filtration according to ISO 8573-1:2010 standard.

Why you benefit from optimal filtration of compressed air?

Clean compressed air ensures process reliability and cost reduction, because the compressor compresses the ambient air drawn in, including all impurities. However, compressing the ambient air also means compressing the impurities. Without appropriate compressed air treatment, the impurities would then enter the compressed air network unhindered and cause damage to products and machines.