Services

3D scan and planning

IMEX Filtertechnika has been using 3D scanning for the measurement and planning of dust collection and filtration systems since 2008. This detailed and millimeter-precise planning has a noticeably positive effect on safe and efficient project implementation.

Modeling projects or plants via 3D scans enables detailed project visualization and coordination with the customer for new designs, long before the first screw is installed. For existing plants, 3D scans can be used to ensure that modifications and adaptations fit perfectly. Existing halls and plants are usually densely filled with a lot of equipment such as gas-water-pressurized air lines, cable trays, light fixtures, radiators, ventilation ducts, crane runways and much more. With our unique 3D scanning technology, we can measure the conditions in a hall with millimeter precision and digitally capture and map existing objects exactly.

Go to 3D Scan case studies

Measurements

- Measurement of air volume, air velocity and volume flow rate

- Noise level measurement

- Efficiency measurement of extraction systems

- Dust Track Measurement of respirable dust and oil mist exposure in the workplace

- Dust Track Measurement of the efficiency of dust and oil mist separation systems

Dust Track Measurement:

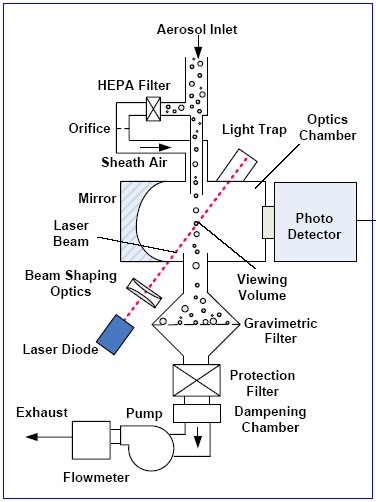

The exhaust air is fed into the measuring instrument via a sampling hose. Part of the air flow is cleaned down to the smallest particles via a HEPA filter. This clean air envelops the exhaust air like a protective shell and thus flows into an optical chamber where it is illuminated with a laser beam.

The light reflected from the particles, aerosols is detected by a detector and converted into digital characters. The air passes through further filters and then leaves the device.

From the amount of air flowing through and the signals of the detector, the current dust load in mg/m3 is calculated and shown on the display of the device.

The measurement data can be viewed via a login.

Service & Maintenance

If you want to prevent equipment failures and costly repairs, regular equipment checks and maintenance are the best investment. Qualified specialists can detect any minor defects and faults during these checks and rectify them quickly before they lead to serious damage.

Of course, the work performed and data measured are logged in detail and any required or recommended actions are recorded in writing. Furthermore, inspections of older systems, for which the operator may have no documentation or technical data, can provide extremely useful information on performance and efficiency.