Textile air distribution systems

Textile air ducting systems are also becoming increasingly popular in Hungary, as they have many advantages over conventional sheet metal ducting generally used in air conditioning and ventilation for fresh air supply.

These are for example:

- lower dead weight

- easy and cheap transport

- quick assembly

- washable, and therefore more hygienic

- environmentally friendly

Further advantages bring the elements that you do NOT need:

- No diffusers, as textile air distribution systems can be used as both air ducts and air distributors.

- No silencers, as the system can transport and distribute the fresh air quietly.

- No insulation, as the system is condensation-free.

- No varnishing, because the textile is dyed by itself.

- No escalating assembly costs, as far fewer man-hours are required for installation.

- No time-consuming tinkering with connecting elements, systems can be planned individually and the individual parts are easy to assemble with zipper fasteners after delivery.

The expansion with textile air distribution systems varies from site to site, but the possibilities are almost endless. Textile air distribution systems are very easy to adapt to the conditions of a hall. All ducts can be equipped with bends, distributors or reducers.

Since you don't have to balance textile systems, you can usually save on the valves as well. This makes planning and expansion for optimal air distribution very simple.

Together with the specialists of the company FabricAir® we are at your disposal for advice and planning!

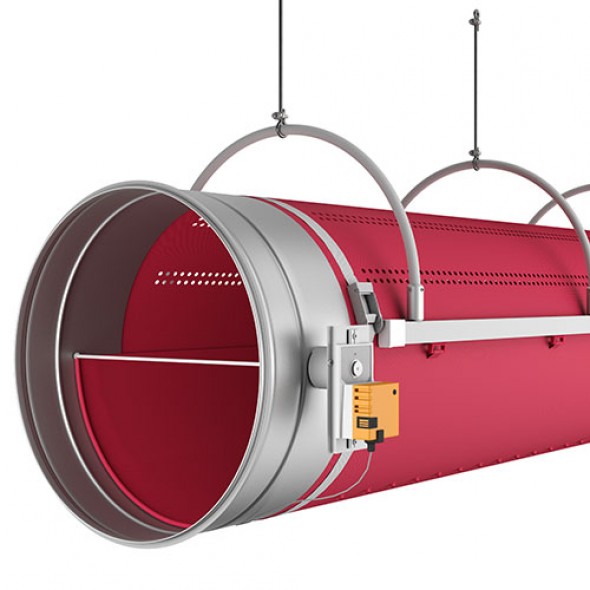

VarioDuct™

The FabricAir® VarioDuct™ system offers different flow models for cooling and/or heating operation. It is equipped with an internal membrane that separates two air flows. Depending on which flow pattern is needed, a damper changes its position and moves the internal membrane either up or down, covering half of the duct.

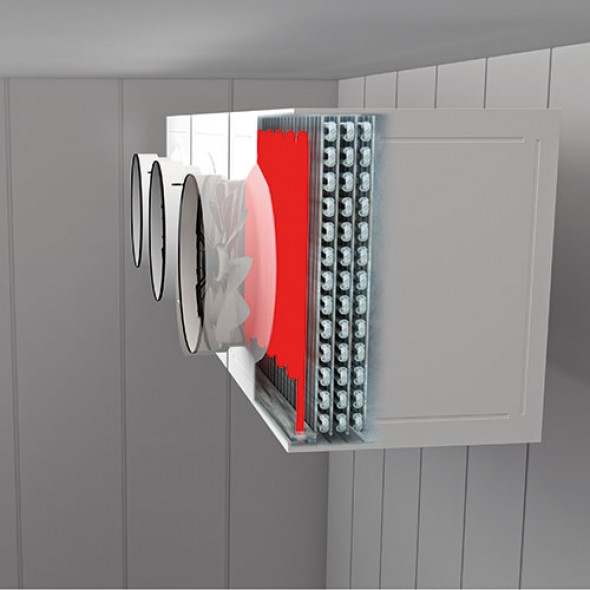

DefrostDuct™

The new and improved FabricAir® DefrostDuct™ increases the efficiency of cold storage air coolers with up to 75% energy savings during defrost. When the evaporator reaches its defrost cycle, the duct collapses, effectively sealing the outlet. By preventing heat from escaping the air cooler, the efficiency of the defrost cycle is significantly increased.

Textil Deckendiffursoren

Textile diffusers provide a draft-free indoor climate in buildings. They offer easy installation, flexible design and environmentally friendly technology. These products are made from two standard fabric components - a mounting frame and a textile flow panel. The diffusers are available for air supply and exhaust, and are suitable for ventilation and cooling conditions.

The air is directed through a flat textile flow plate, which allows the diffuser to match the suspended ceiling tiles. In addition, even the pattern can be requested according to individual wishes, so that the flow plate blends almost invisibly into the suspended ceiling.

RapidSlider: Faster assembly of the fabric ducts - seamless, shapely aesthetics

The RapidSlider is a specially developed system of keder, rail and special feeder that makes it possible to quickly and easily connect a fabric element to a frame. With the help of plastic beads, the keder is slid into a rail that resembles a zipper. The sliding function in combination with the specially designed FabricAir feeder thus enables faster and more efficient assembly of many types of textile air ducts.