Extraction systems

In industry, fine dust or suspended dust is generated during numerous processes such as transport, conveying and mixing of dusty materials, thermal processing of metals or other materials such as casting, cutting or welding, and mechanical material processing such as grinding.

To protect people and machines, it is therefore important to extract welding, plasma and laser fumes as close to the source as possible and not allow them to escape into the environment. Today, there are numerous options and technologies for individual solutions in every working environment.

How does an extraction system work?

Each dust collection system is unique and individually adapted to what needs to be filtered and protected. Depending on the manufacturing processes, welding fumes, powder coating emissions, grain dust, oil mist and much more are generated. At the beginning of the planning process, it is therefore important to know exactly all the details in the process, such as:

- Special properties of dust - from abrasive to explosive

- Where and when does what amount of dust occur - permanently or only situationally, large amounts or small?

- In which environmental situation is the plant located?

- Who and what all must be protected from dust exposure?

- Which legal requirements and regulations must be observed?

The better the knowledge of this, the more accurately and efficiently the dust collection strategy can be determined and the right choice of dust collection equipment can be made.

The most widely used dust collectors are

- Bag or bag filter

- Pocket or bag filter

- Cartridge or cassette filter

Of course, the separation of dirt particles is also possible by mechanical means, but due to their low efficiency, these systems are usually only used as pre-separators. These are e.g.

- Pre-separator with stop plate

- Cyclone separator or

- Axial cyclone separator

However, before turning to separation and filtration, the collection, extraction or capture of the dust in question must be solved. It is not always possible to remove the dust immediately where it is generated. Therefore, the movement and transport through ducts and pipes must be planned to be as efficient and space-saving as possible.

However, how dusty air is extracted is not described in any standard or regulation; only the laws of physics apply. In addition to complicated calculations from physics, the knowledge gained from years of practical experience is therefore the best guarantee for a successful extraction system.

Parameters to be taken into account for efficient extraction

- Dust content of the extracted air (g/m3)

- the emission intended to be achieved (mg/Nm3)

- the dust substance, particle size distribution, other physical and chemical properties

- Temperature and moisture content of the air-dust mixture and the environment, risk of condensation.

- Occurrence of other contaminants in the air stream, such as oil mist, paint particles, pollen, vapors or gases

- Explosion and fire hazard

- how to discharge the separated dust or turbidity from the filter bunkers

- the use and after-treatment of separated dust or the turbidity

- available space, indoor or outdoor installation

- daily operating time

- Investment and operating costs, energy consumption, heat recovery, etc.

- And much more ...

Industrial dust collection systems require a high degree of professionalism, experience and up-to-date technical knowledge, especially in the planning phase.

Two case studies for insights into the diverse world of industrial dust collection:

High-tech products require high-tech plant engineering and stable

As part of a structural components project, one of the most modern production lines in Europe has been built at the Hungarian Prec-Cast plant of the German Wolf Group. The goals of this project were lean production, small buffer volumes, fast cycle and throughput times, and high line availability.

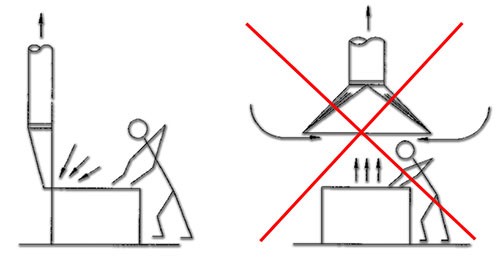

Optimum occupational safety thanks to push-pull systems

Push-Pull is a solution that has proven itself very well for keeping the ambient air clean in production halls and everywhere where the selective collection of polluted air is not possible.

Read more about how it works and specific recommendations in our case study.