Case studies and technical articles

Stationary welding fume extractors class W3 in the smallest possible space

Three powerful, efficient extraction systems with minimal space requirements for the extraction of three state-of-the-art welding robots. An important objective was to adapt the piping to the local conditions in order to ensure access to the robots for maintenance work. These were the requirements for our latest project at Güttler Kft. in Hungary in cooperation with Flexman Robotics.

One central oil mist extraction for all machines

Fertigungstechnik Rachbauer GmbH is a specialist for turning and milling of cast iron, steel and aluminum. Our task was to plan and install a customized emulsion mist extraction system for the large, constantly growing machine park for CNC turning, milling and grinding.

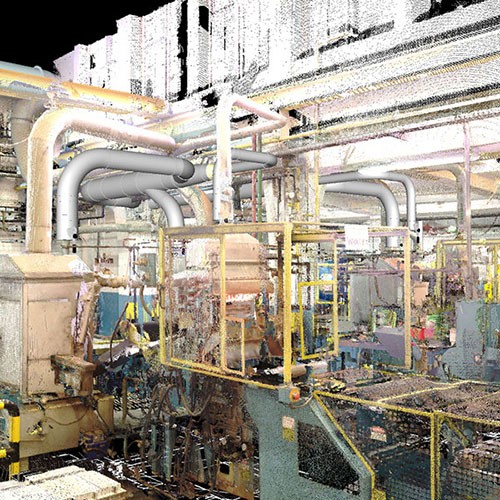

The advantages of 3D planning based on 3D scans

In 2021, IMEX Filtertechnika applied to the tender for the renewal of a dust extraction system at Bayer Hungaria Kft. whose design was no longer effective enough.

Effective solutions through professional planning and visualization

One of the most recent tasks for a long-standing customer - Sealed Air Hungary Kft - was to upgrade its exhaust system to adapt it for a higher production level.

Cost savings through complete filter replacement for dust collectors.

What sounds like a contradiction is actually true. In a sensitive and precise system like a dust collector, a complete filter change is more cost-effective and efficient than replacing it piece by piece when it fails. In the following article, we explain why this is so and how you can use it to make system maintenance as economical as possible.

High-tech products require high-tech plant engineering and stable peripheral technology

As part of a structural components project, one of the most modern production lines in Europe has been built at the Hungarian Prec-Cast plant of the German Wolf Group. The goals of this project were lean production, small buffer volumes, fast cycle and throughput times, and high line availability.

Case study: 3D scanning and planning

We recently used 3D scanning and planning for the first time in Austria for the efficient and safe modernization of an extraction system. We have summarized the details in a case study.

Compressed air management for dedusting systems reduces costs

Compressed air is a very valuable resource in industrial production, as it is energy-intensive. Therefore, economical use in all applications has an immediate positive effect on the operating cost balance of systems. In our article we are giving an account about which filtration measures are particularly efficient and recommendable for industrial dedusting systems.

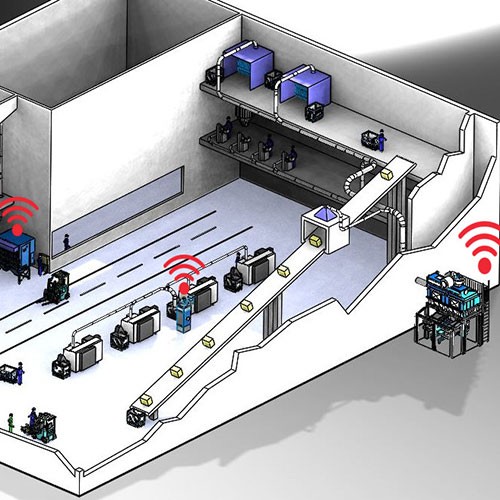

Our contribution to Industry 4.0 – The FMS Remote Filter Monitoring System from IMEX Filtertechnika

IMEX Remote FMS is a remote measurement system which had been first and foremost developed to remotely monitor our installed dust collectors, but thanks to continuous development, today it can be flexibly integrated into ventilation-, air-conditioning and basically every other system, where there is a need of review and log function states and parameters remotely.

Optimum occupational safety thanks to push-pull systems

Push-Pull is a solution that has proven itself very well for keeping the ambient air clean in production halls and everywhere where the selective collection of polluted air is not possible. Read more about how it works and specific recommendations in our case study.